Efficient freight management is crucial for seamless logistics processing within the supply chain. It can be supported by a web-based and individually configurable supply chain management platform that ensures a high level of transparency and thus better coordination of processes. So how can companies manage their transports in a targeted manner and thus take advantage of the benefits of such a digital system to optimize their supply chain? Christian Krogmann, International Manager at Hermes International, a division of Hermes Germany, discusses these and related questions.

What are the advantages of SCM software for freight management?

In supply chain management (SCM), the higher the supply chain visibility, the better it can be controlled. SCM software ensures high transparency by visualizing each individual transport section along the value chain – in real time.

The digital and networked exchange of information enables control and flexibility far better than a conventional data exchange via Excel spreadsheets or via e-mails. Thus, freight managers can trace where their delivery is at any time and control further progress accordingly. Real-time visibility is particularly relevant in the event of delays or obstacles: the transport route can be adjusted immediately, further transports can be planned in advance, and recipients of the goods can be informed ahead of time.

A web-based version like the one we use for our customers is particularly convenient – with cloud solutions, the usage configuration is very flexible and the costs can be quickly amortized through the increased efficiency.

What functions does the web-based SCM platform offer?

Users receive personalized access to the web-based SCM platform and thus location-independent access to their freight data. The platform can be used in modules – we evaluate which applications make sense in a detailed consulting process prior to the implementation phase. Initial configuration is also part of our service, as we adjust the settings according to requirements and customer preferences.

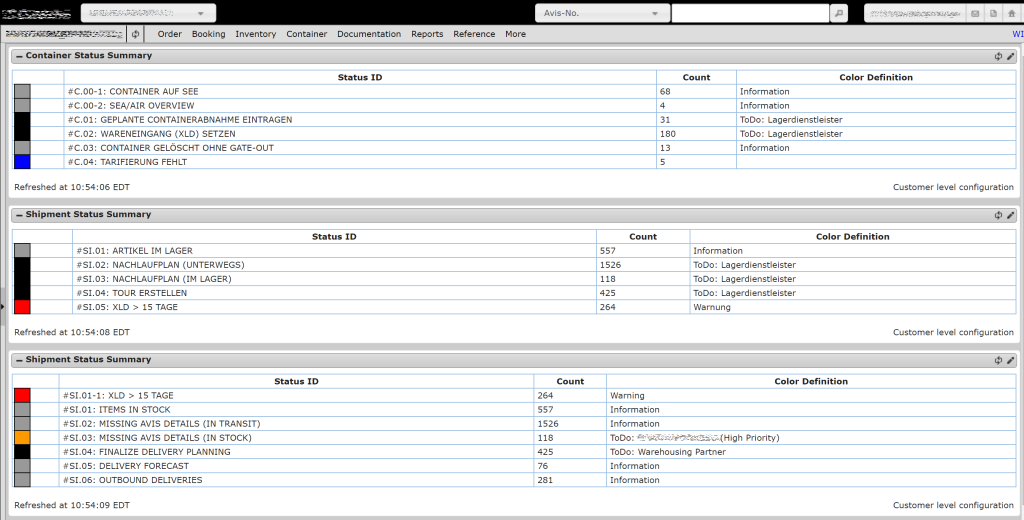

One example from practical experience: After logging in, the freight overview appears on the customized dashboard. With the help of a search function, individual or multiple containers can be called up simultaneously by container, B/L or AWB number. The associated events and milestones are displayed in a well-structured list in chronological order. This allows for a detailed overview of which containers are on their way by sea, have just arrived at the port of destination, are waiting at the transshipment port for onward transport or are already on their way to the warehouse.

Current planning data for the further route is also displayed. The real-time visualization offers particular added value. It shows delays or disruptions on the transport route in a traffic light system. If the transport does not proceed according to schedule, the company can intervene in time and, for example, reschedule to an alternative mode of transport. Container layover times in the port are also displayed transparently, allowing shipments to be prioritized in the on-carriage phase in order to avoid rapidly escalating costs for demurrage or detention.

Keeping track of things is easy: The individual dashboard

How detailed is the insight of a SCM software into the freights?

The detailed view contains standard information about each container – for example, its number and size. There is also information on weight, volume, B/L number and, with the number of packages contained, details on loading. Also worth mentioning in this context is the “Event Management” tab: here, information on the individual events and corresponding forecasts ensure that flows of goods can be optimally controlled.

The system thus offers complete transparency and users always have an overview of which goods are currently at which milestone. Every step along the supply chain is transparently traceable. From dispatch in the country of departure to arrival at the port of destination, gate out with the on-carriage carriers to the destination warehouse and return of the container empty at the depot.

If the company wants to handle individual process steps via the SCM platform, we can map the to-dos in detail and in chronological order using a workflow management. The platform also provides the “Online Documents” feature – this allows all transport documents to be managed digitally, from the order to the booking to the shipment. That way, the commercial invoice or the packing list can be stored, for example.

Where does the SCM platform receive the data and thus, how do the users optain the relevant information?

On the platform, we connect various players in the supply chain, who then feed key milestones into the system. How this happens precisely depends on the organization of the respective supply chain. One example: the supplier in the procurement market transmits data on goods deliveries to our logistics partner on site.

This can be done digitally via a previously implemented IT interface or, if that is not possible, by manual means. In this case, the supplier submits the data in the conventional way and either the company itself or our team or corresponding service providers take over the service of entering the data into the system.

A wide range of data from various partner- and service provider systems converges on the platform, providing a transparent view of the status of processing. Data providers include leading shipping companies, third-party forwarders and airlines. The operational employees at Hermes International also work with the SCM platform and are thus always cooperatively involved in the process.

Christian Krogmann

International Manager

Hermes Germany

How does the SCM software contribute to long-term optimization?

In addition to visualizing the transport route, extensive data evaluations are possible. For example, supplier performance can be tracked over a longer period of time and it can also be broken down with which supplier delays occur more frequently.

In this context, transparency offers support for supplier evaluation and management, and, if necessary, for joint optimization of processing. Predictive data can also be used to analyze existing transport runs and adjust them accordingly. The individual evaluations thus offer a wide range of optimization potential for making freight management efficient and crisis-proof.

You ask – we answer!

Would you like to learn more about freight management and the benefits of an SCM platform, or are you interested in other topics related to logistics and supply chain management? Feel free to send us your questions by e-mail at fragen@hermes-supply-chain-blog.com and we will forward them to our team of experts.

Your personal data will be processed in accordance with our privacy policy.